Home > About Us > Factory Tour

Factory Tour

Foundry

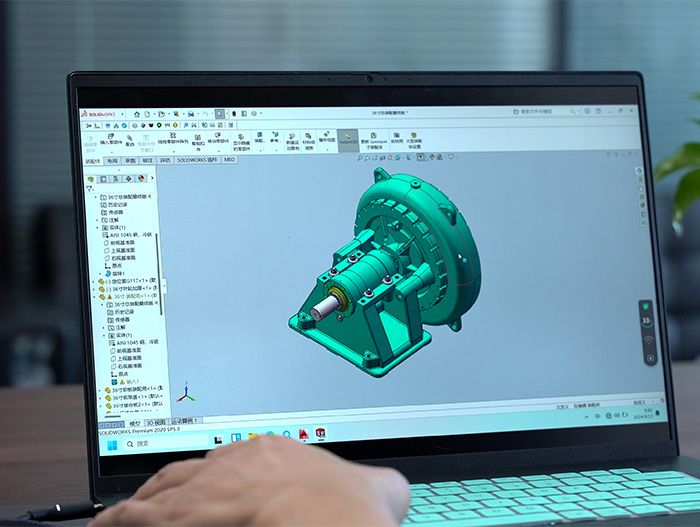

Advanced Hydraulic Design

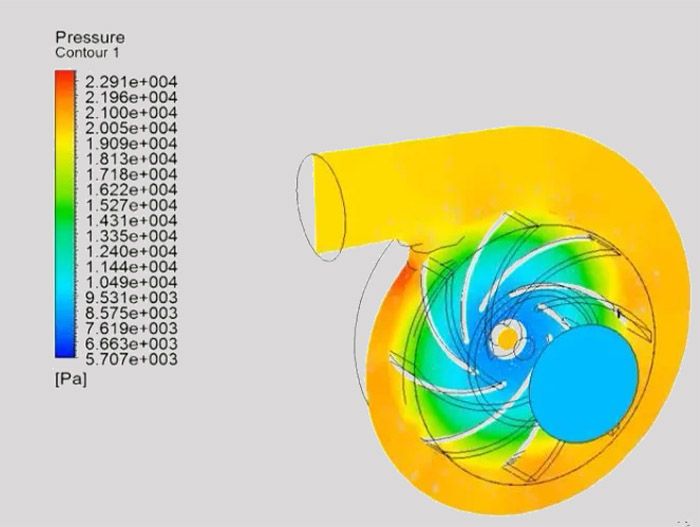

CFD Analysis Technology

Caption Foundry

Heat Treatment

Machining

4m Vertical CNC Lathe

High Precision Boring Machine

CNC Machining Center

Shot blasting machine

Assembly

Modern Assembly Shop

Detail Precision Assembly

Dust-Free Bearing Assembly Workshop

Professional Assembly Engineer

Performance Testing

Performance Test Platform

Flow & Pressure Inspection

Pump Speed Test

Pump Vibration Test

Exquisite Quality Display

Free-Dust Assembly Room

Spary Baking Room

Welding Robot

Specific Designed Accessories

Ready Pumps and Delivery

Complete Display

Complete Display

Batch Display

Batch Display